Problems needing attention in CNC machining of carbon fiber composites

Release time:

2020-08-17

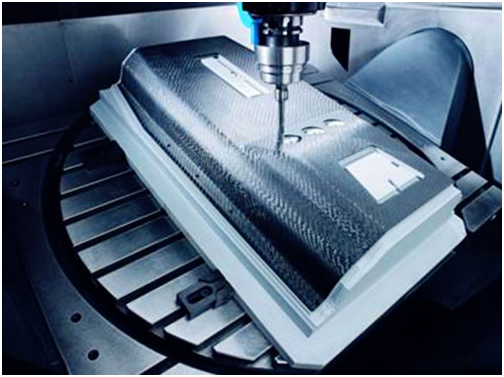

Carbon fiber composite materials have high strength and rigidity, and their application range is becoming wider and wider, but it is difficult to process because of the superior performance of the material itself. At present, carbon fiber products are mostly processed by CNC for punching, cutting, hollowing out and other operations. If you want to reduce the difficulty and efficiency of processing, you must know the characteristics and processing characteristics of carbon fiber composite materials. Follow Rui Control Machinery Technology to learn about the problems that need to be paid attention to when CNC processing carbon fiber composite materials.

?

At present, carbon fiber composite materials are mostly composite materials using resin as the matrix. After the resin is cured, the hardness and strength are not very large, and it is not difficult to process,However, a problem faced in the processing process is that the overheating temperature during the processing will soften the resin or even burn it, which will cause damage to the entire carbon fiber product that is difficult to repair. The characteristics of carbon fiber is very high tensile strength, hardness is also very large, but it is relatively easy to cut when subjected to shear stress, which requires taking into account the complex relationship between cutting force and deformation.

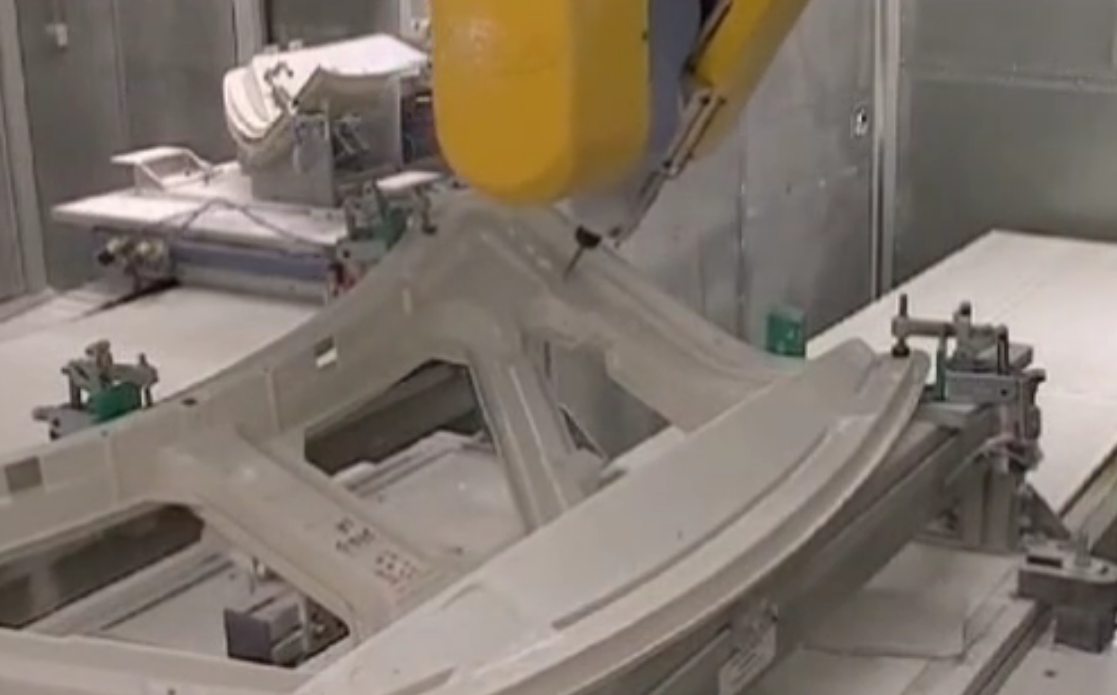

When processing complex and precise carbon fiber structural parts, in order to avoid the influence of oil pollution on the parts, there are often dry cutting requirements without coolant,The shape of such parts is complex, and the overall strength and hardness of the fiber layer are very high. Processing will produce a very high temperature. Not only the processed parts are easy to soften and scorch, but also the loss of processing tools is very serious. Because such carbon fiber products often have high precision requirements, so in the processing of such products need to choose wear-resistant, heat-resistant non-sticky processing tools.

In the process of processing carbon fiber composite materials, the rake angle of the processing tool should be selected with an appropriate small value, which can effectively dissipate heat and increase the cutting edge strength,However, it can not be too small sharp enough, for this high toughness and strength of the material can not be effectively processed. In order to reduce the wear of the tool, the rear angle of the knife is selected to be large. CNC machining of carbon fiber composite materials using the best choice of CVD diamond tools, because this wear resistance is the best, the cut out smooth, the best quality. Alloy tools in the processing will appear serious loss, and easy to burn the product.

Carbon fiber composite CNC machining requires careful control, otherwise it is easy to cause damage to the product, so customers and friends in the processing of productsBe sure to pay more attention. nantong rui control machinery technology specializing in precision 3-5 axis cnc machining center of production and sales, with senior carbon fiber composite material processing experience, welcome to discuss cooperation.

Related News