Application of Heidelhain Encoder in Industrial Robot

Release time:

2020-07-26

Speed, power and durability are important characteristics of industrial robots. Industrial robots are usually used in automobile assembly lines for welding and handling of heavy workpieces. Despite the use of advanced calibration methods, the position accuracy of industrial robots is still not ideal in performing some tasks. Now, this situation has been changed by the high-precision output encoder of Heidhan and its sub-brand AMO.

The encoder was developed primarily to meet the requirements of aerospace applications, where large workpieces must be machined with high precision. It is not difficult for machine tools to achieve high precision, but the flexibility is insufficient or the cost of special machine tools and special processing workshops is too high. However, the robot can easily reach any position of a very large workpiece, such as the fuselage of an aircraft, where it can be drilled or milled.

?

?

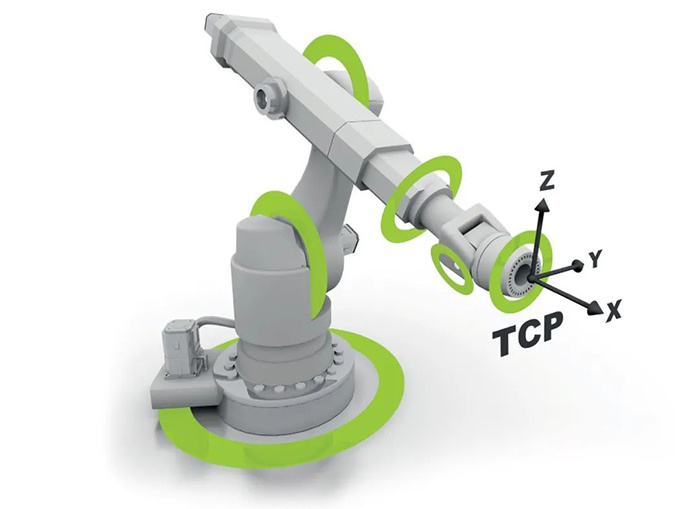

For this type of application, the tool center point (that is, the tool at the end of the robot arm) must be positioned and oriented with sufficient accuracy. Traditional industrial robots are close to their limits in this regard. There are several factors that contribute to the bias:

1) In order to achieve the required mobility, it is necessary to use a serial motion robot, such as a six-axis articulated robot.

2) Each of the shafts is driven by a geared servo motor. The error mainly comes from zero error, backlash and connection elasticity.

3) In machining, the force and dynamic force affect the rigidity of the robot mechanical system, thus affecting the absolute position accuracy.

With advanced calibration methods, it is now possible to control the accuracy of the repetitive fixed-point motion of the tool center point to within a few percentage points of a millimeter. Some manufacturers' articulated robots have a repeatability accuracy of ± 0.1mm or higher as required by ISO 9283.

However, this is still 10 times lower than the repeatable absolute position accuracy achievable in the robot coordinate system. According to the robot structure design, maximum range and maximum load, the absolute position accuracy of articulated robots is now ± 1mm. This kind of precision can not meet the requirements of aerospace and other industries. Therefore, robot manufacturers must face up to this problem.

?

Method 1. high dynamic performance motor control

?

?

A conventional rotary encoder provides a continuous feedback signal to the servo motor of the robot motion axis. Since servo motors require a high control dynamic range, Heidelhain's rugged inductive rotary encoders, such as the ECI 1100 and 1300 series or multi-turn EQI 1100 and 1300 series encoders, are ideal for such applications. These encoders control high quality and high precision, and can withstand strong vibration. Because these encoders are equipped with a pure serial EnDat interface, even if they are used in a strong electromagnetic interference environment, they do not affect the quality or safety of data transmission.

These inductive rotary encoders support SIL level 2 and 3 PLd safety. If measures are added to the control system, SIL level 3 or 4 PLe safety is also supported. These encoders also offer an additional safety advantage, protection against mechanical failures and a loose connection between the shaft and the stator. These safety measures make these inductive rotary encoders particularly suitable for man-machine cooperative systems.

?

?

Method 2. auxiliary encoder for high precision position measurement

?

?

?

If a high-precision angular encoder or rotary encoder is added to each axis of the robot, the robot manufacturer will be able to significantly improve the absolute position accuracy of the robot. The additional encoder is an auxiliary encoder, which is installed at the rear of each gear transmission and measures the actual position of each joint of the robot. In this design, these encoders will address the null error and backlash issues. It can also measure the reaction force of each axis in the process. All these factors will improve the absolute position accuracy of the tool center point by 70 to 80%.

?

?

Method 3. high precision position measurement of mobile robot

?

?

?

In order to reach all machining positions of large workpieces or long parts, such as the production of aircraft fuselages or large composite fiber workpieces, the robot needs to move along a linear axis in the direction of the length of the workpiece. In order to ensure high-precision positioning of the robot, Heidelhain provides linear motor drives and closed linear grating scales with a length of up to 30 m. The position measurement of the linear grating ruler can compensate for thermal displacement and other factors that affect the error of the feed mechanism. These influencing factors cannot be detected by the traditional position detection method of the ball screw pitch and the angle position of the rotary encoder in the motor.

?

?

Conclusion: High-precision position measurement improves the position accuracy of the tool center point

Equipped with an auxiliary encoder for each axis of the robot and the use of a linear grating ruler to measure the position value in the relative workpiece positioning robot will significantly improve the position accuracy of the tool center point, ensuring that the properly configured industrial robot can position and process with high precision and perform operating tasks on the workpiece.

Heidhan and AMO's angular encoders and linear grating rulers not only meet the system requirements for high precision, but also meet the requirements for flexibility in installing encoders in complex and compact robotic mechanical systems. These encoders are suitable for security applications and therefore for systems with human-machine collaboration.

?

?

Related News