What is a vertical machining center for a precision electronics mold manufacturer?

Release time:

2020-07-16

With the continuous improvement of people's consumption level, higher requirements are put forward for the quality and personalization of products. Electronic product manufacturing industry mold manufacturers to mold as a work of art to process, the processing accuracy and surface quality of the extremely demanding requirements, but also requires a very short delivery time.

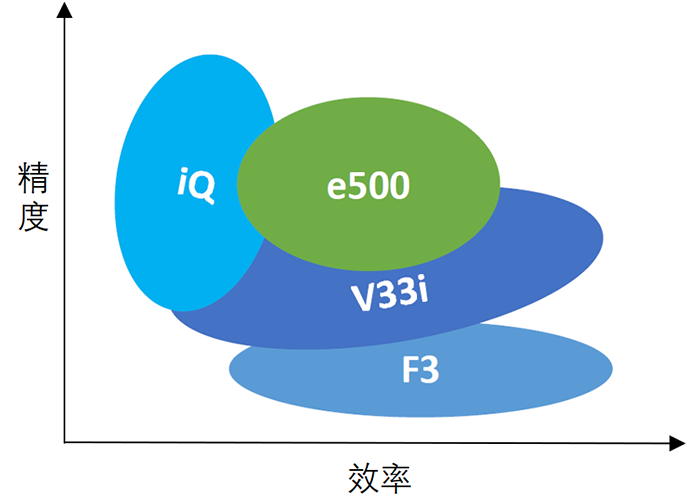

As we all know, vertical machining center is one of the most important equipment in precision mold manufacturing. As the benchmark of the industry, Makino Machine Tool has successfully introduced F series, V series and iQ series vertical machines to the market. With the higher requirements of the electronics industry for processing accuracy and efficiency, the Muye R & D team once again broke through the limit and built a new generation of vertical machining center e500.

?

Makino New Generation Vertical Machining Center e500

?

Makino e500 series has the characteristics of high rigidity and high efficiency of V33i series, and its processing accuracy can be comparable to that of iQ series with ultra-high precision. Thus, the comprehensive performance of the vertical machining center will lead to a new level.

?

?

It is named after the English letter e, because this machine tool is specially developed for the electronic product manufacturing industry (EMS), and it also has multiple meanings:

high reliability.

High rigidity mature structure, 3 axis linear motor

efficiency high efficiency

30000RPM electric spindle, can realize Φ8mm tool opening

extra-high accuracy ultra-high precision

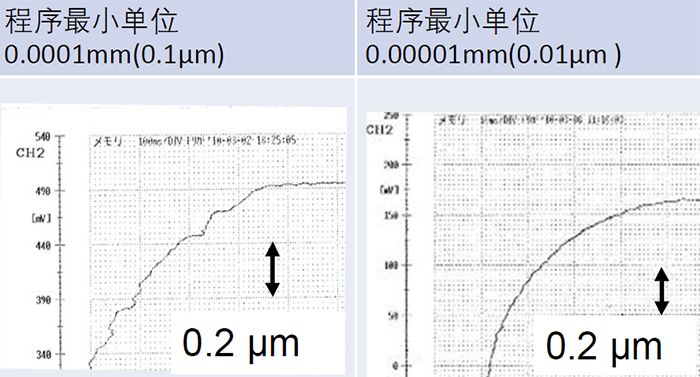

Program resolution 0.00001mm (5 decimal places)

Grating resolution 0.00000125mm(1.25nm)

eco energy saving and environmental protection

Water-cooled freezer, the heat discharged from the equipment is not in the workshop

Easy to use

Pro6 control, simple and easy to use, the dependence on people to reduce to a very low

?

1. e500 machine features

1) High rigidity and high reliability

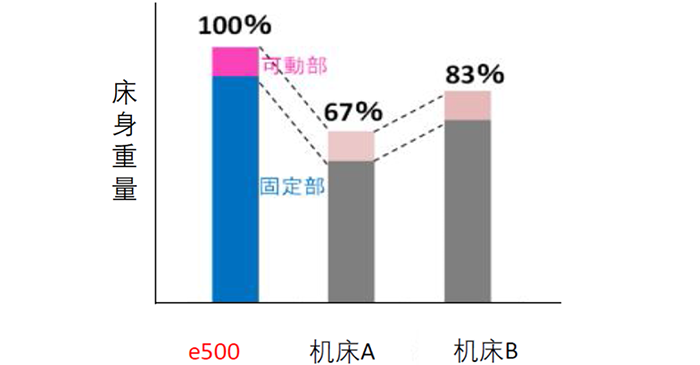

The weight of the bed of 8400kg and the unique structure can make the movable part lightweight. The independent structure of XY axis ensures the high rigidity of the feed shaft. It is equipped with the feed shaft independently developed by Makino and SGI. 5 control function, under the premise of constant quality, the processing efficiency is increased by 30% (the premise of high speed is to ensure accuracy).

?

?

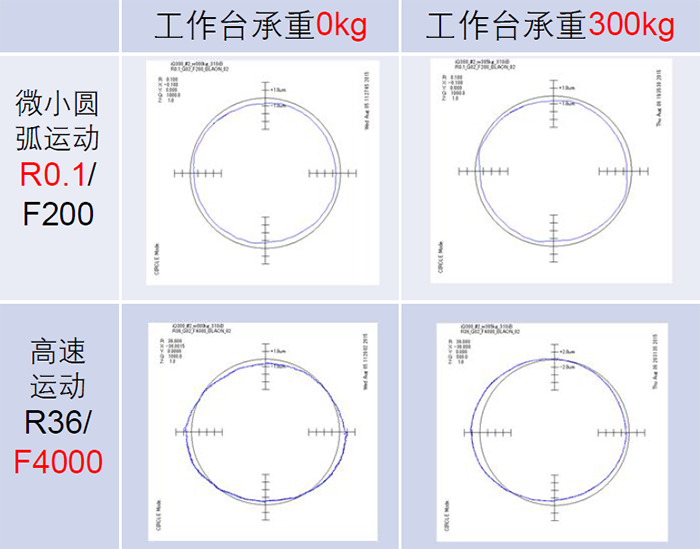

2) Ultra high precision characteristics

Roundness <1μm, and does not change with load-bearing and feed changes; The resolution of the grating ruler reaches 1.25 nanometers, and the program resolution can reach 5 digits (0.00001mm) after the decimal point, which fundamentally has the characteristics of high-precision micromachining.

?

Roundness <1μm

?

Comparison of arc trajectories at different resolutions

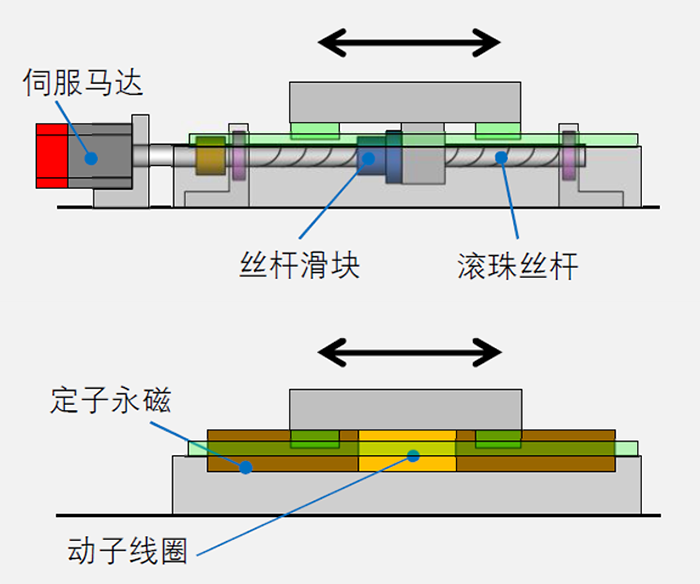

3) Linear drive

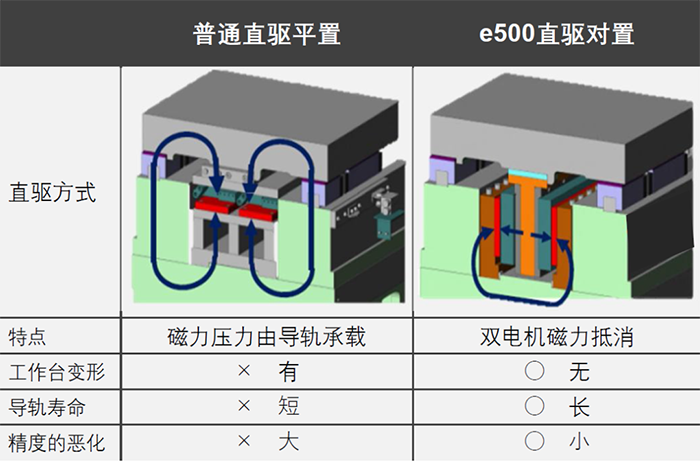

Compared with ball screw drive, linear motor drive does not have screw backlash when the motor reverses, but heat generation and end effect are the difficulties of linear motor. Makino adopts spindle center cooling technology, and the linear motor stator and mover are cooled separately, effectively overcoming the technical problems. Compared with ordinary linear drive, the direct drive of Makino will not increase the pressure of worktable and guide rail and affect the processing accuracy.

?

Comparison of ball screw drive and linear motor drive

?

Comparison of ordinary direct drive flat and e500 direct drive opposed

?

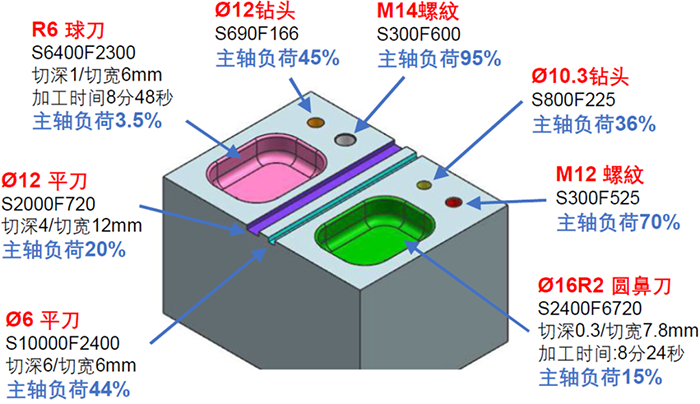

4) 30000 rotation spindle rigidity

30000-turn motorized spindle (HSK-E50) processing capacity:

Material: S50C

Size: 200x150x150mm

Groove size: 60x80x20mm

?

?

2. e500 machine tool machining case

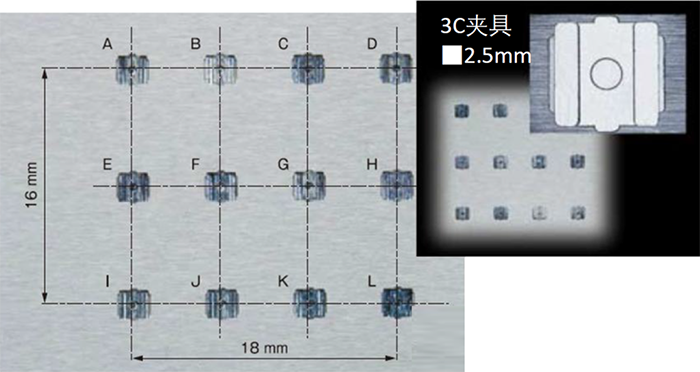

1) high precision fixture plate efficient processing

Material: SUS420J2 (HRC52)

Size (Slot): 8 x 6 x 3.5mm

Processing beat: 480 minutes/48 slots

XYZ positioning accuracy <1μm

Dimensional accuracy <1μm

?

?

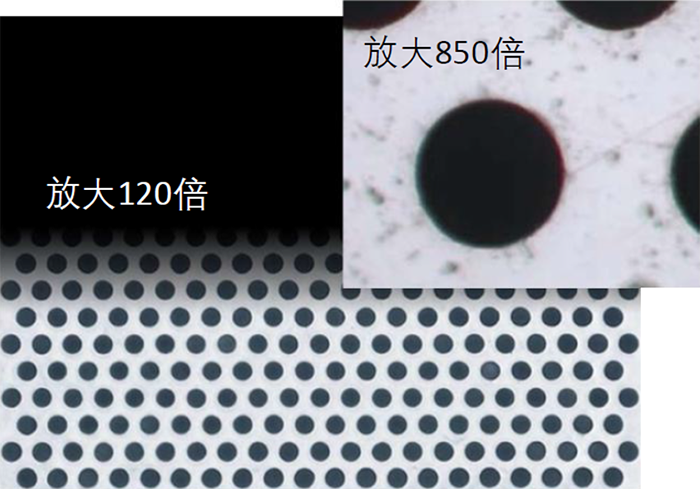

2)Φ0.03mm hole processing

Spindle speed S25000

Material SUS304, thickness 0.15mm

One drill for machining more than 200 hole

Processing time 69 seconds/hole

?

?

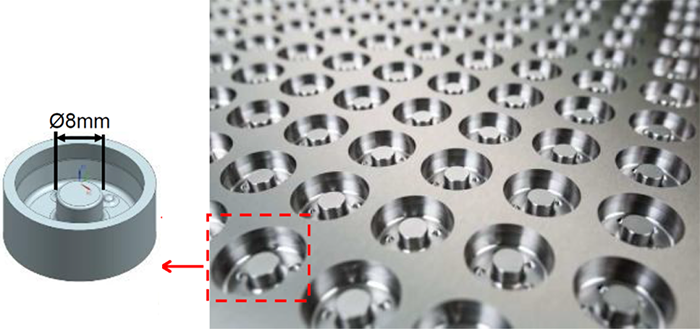

3) precision fixture processing

Material NAK80

Use tool Φ0.2mm end mill

Processing feed F200mm/min

Center position error <1μm

Roundness:<1μm

?

?

4) Multi-cavity mold processing case

Material: NAK80(40HRC)

Size: 500x500x30mm

Use tools: 5 kinds of 11

Processing time: 72 hours 26 minutes

Finishing 1 tool to machine 225 shapes

Maximum size error: 1.2μm

?

?

At a time when the electronic product manufacturing industry has higher requirements for quality and efficiency, Makino has launched a new generation of vertical machining center e500 to meet the needs of the industry, which will surely become another tool for electronic component mold manufacturers to enhance their competitiveness.

Related News